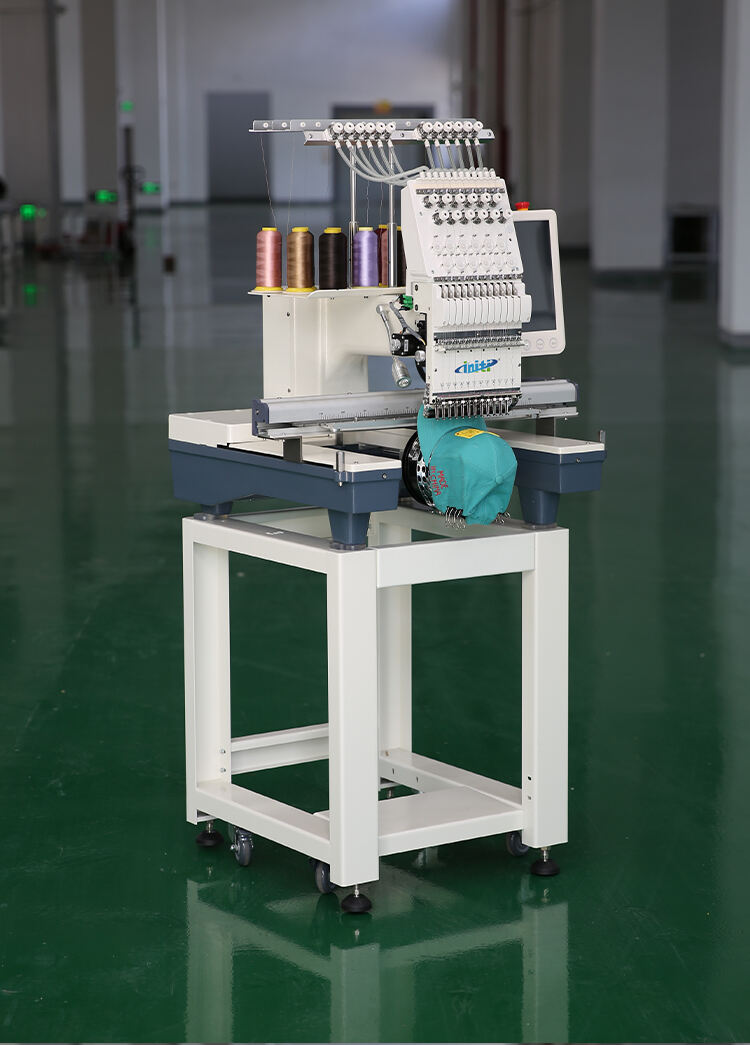

wholesale industrial embroidery machine

The wholesale industrial embroidery machine represents a pinnacle of modern textile manufacturing technology, offering high-speed, precision embroidery capabilities for commercial applications. These robust machines feature multiple heads, typically ranging from 4 to 12 positions, enabling simultaneous embroidery of identical designs across multiple garments. Advanced computerized systems control thread tension, color changes, and design implementation with exceptional accuracy. The machines incorporate sophisticated touch-screen interfaces for easy pattern selection and modification, while automatic thread trimming and breaking detection systems ensure consistent quality output. They support various embroidery types, including flat, cap, and 3D embroidery, with adjustable speeds reaching up to 1,200 stitches per minute. The machines are equipped with large embroidery fields, typically 500mm x 400mm per head, accommodating diverse design sizes. Built with industrial-grade components, these machines feature automatic oiling systems, robust frame construction, and high-capacity memory storage for thousands of designs. They support multiple file formats and offer network connectivity for seamless design transfer and remote operation monitoring.