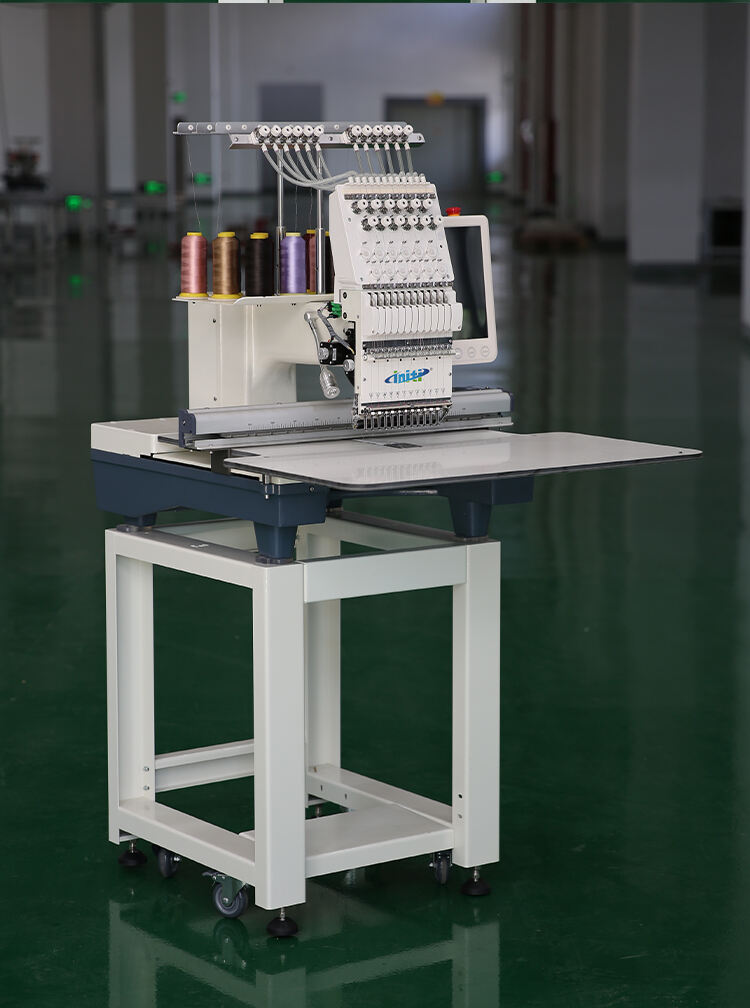

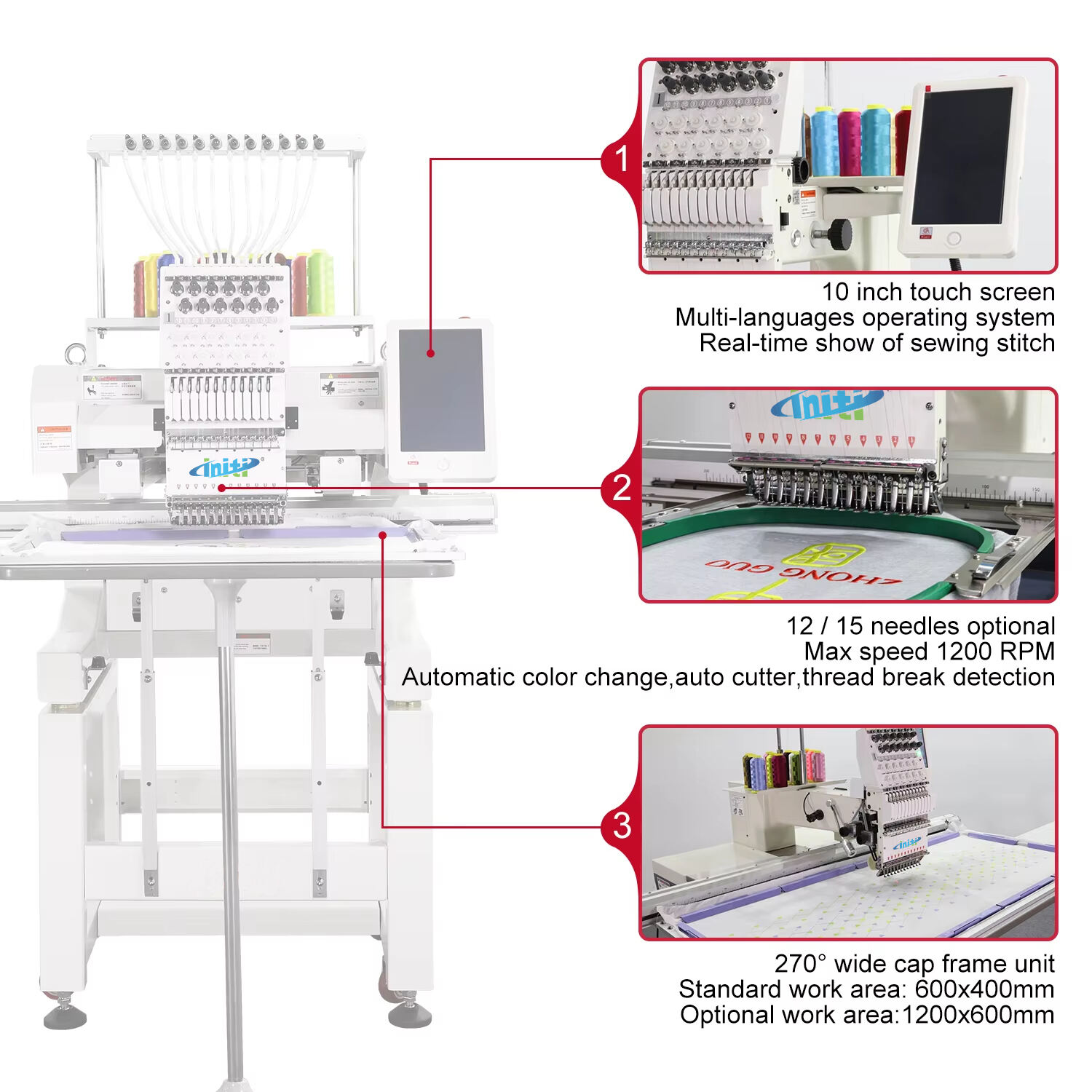

durable industrial embroidery machine

The durable industrial embroidery machine represents a pinnacle of modern textile manufacturing technology, engineered to deliver consistent, high-quality embroidery results in demanding commercial environments. This robust machine features a heavy-duty construction with reinforced components designed to withstand continuous operation across multiple shifts. At its core, the machine utilizes advanced servo motors and precision control systems that ensure accurate stitch placement and smooth operation at speeds of up to 1,200 stitches per minute. The machine comes equipped with multiple needle heads, typically ranging from 6 to 12 needles, allowing for complex multi-color designs without manual thread changes. Its large embroidery field accommodates designs up to 500mm x 350mm, making it suitable for a wide range of applications from small logos to large decorative patterns. The user-friendly interface includes a high-resolution LCD touchscreen display that provides easy access to design editing, machine settings, and real-time monitoring features. Built-in memory can store thousands of designs, while USB connectivity enables quick transfer of new patterns. The machine incorporates automatic thread trimming, thread break detection, and frame out functions to minimize downtime and maintain productivity. These features make it an ideal choice for commercial embroidery shops, garment manufacturers, and custom apparel businesses seeking reliable, high-volume production capabilities.