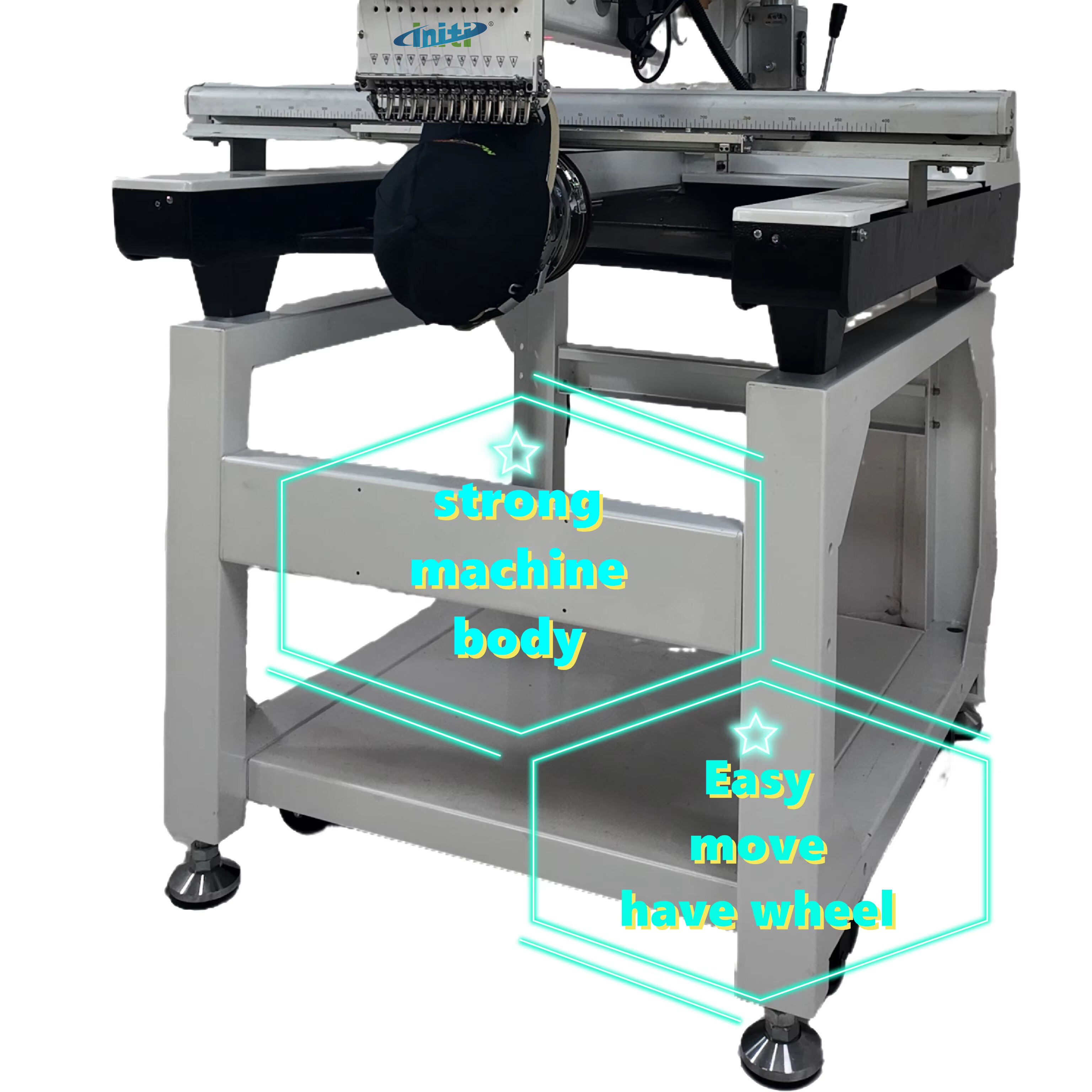

low price industrial embroidery machine

The low price industrial embroidery machine represents a significant advancement in textile manufacturing technology, offering professional-grade embroidery capabilities at an accessible price point. This versatile equipment combines robust construction with user-friendly operations, making it ideal for small businesses, startups, and established manufacturing facilities. The machine features a high-speed operational capacity of up to 1000 stitches per minute, multiple needle configurations, and an automated color-changing system. Its digital control panel enables precise pattern manipulation, while the built-in memory can store thousands of designs for quick access. The machine accommodates various fabric types, from delicate silks to heavy denims, with automatic tension adjustment ensuring consistent stitch quality. Advanced features include automatic thread trimming, break detection systems, and frame out capabilities. The machine's compact footprint maximizes workspace efficiency while maintaining industrial-grade performance standards. Compatible with major design software formats, it seamlessly integrates into existing production workflows, offering both USB and network connectivity options for design transfer. This combination of functionality and affordability makes it an ideal solution for businesses looking to expand their embroidery capabilities without substantial capital investment.