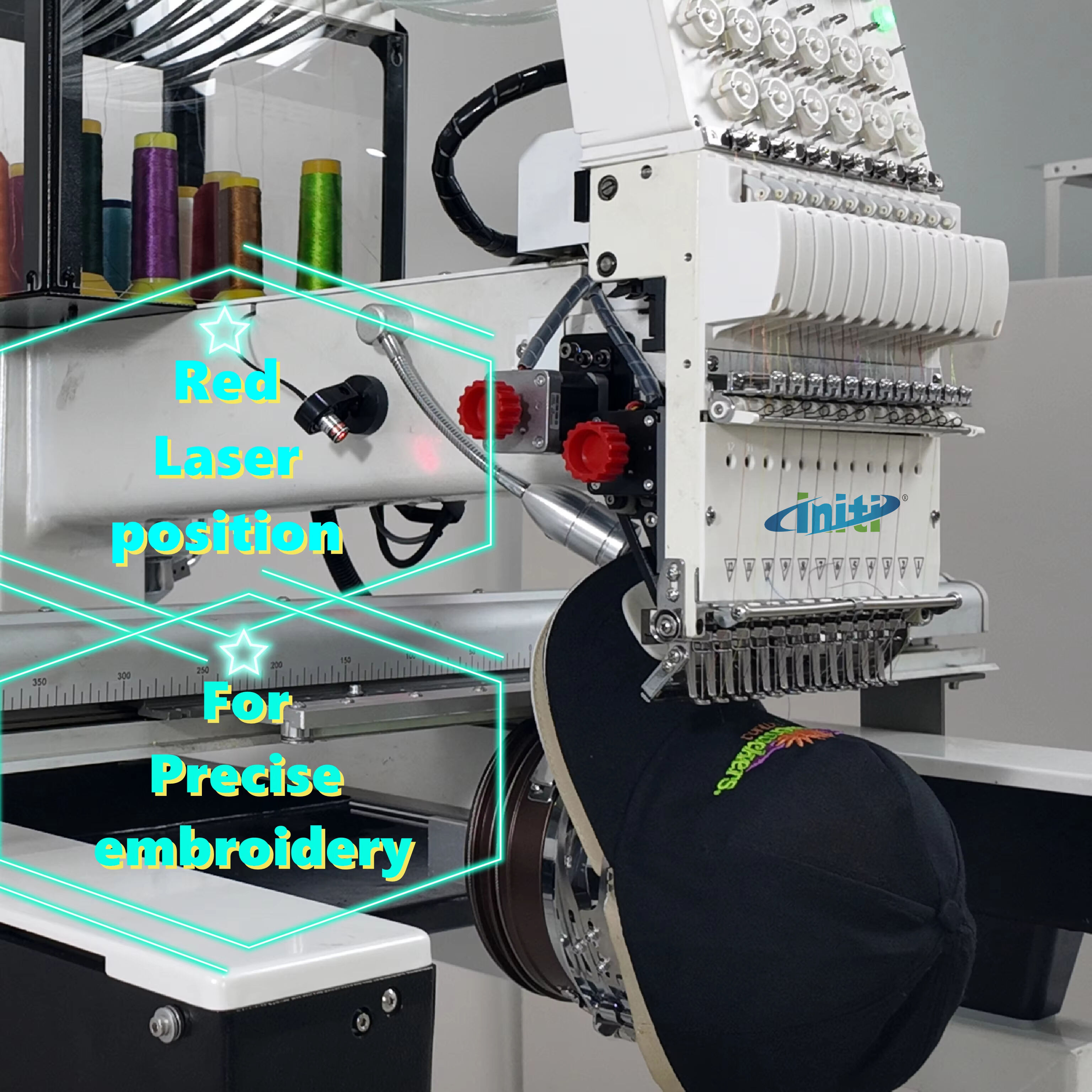

quality industrial embroidery machine

A quality industrial embroidery machine represents the pinnacle of precision textile manufacturing technology. These sophisticated machines combine robust mechanical engineering with advanced digital controls to create intricate embroidery patterns on various fabric types. Modern industrial embroidery machines feature multiple needle heads, allowing simultaneous embroidery of different colored threads, dramatically increasing production efficiency. They typically operate at speeds of up to 1,200 stitches per minute while maintaining exceptional stitch quality and consistency. The machines are equipped with automatic thread trimming systems, thread break detection, and user-friendly touchscreen interfaces that simplify operation and maintenance. Advanced models incorporate networked connectivity for pattern uploads and real-time monitoring. These machines can handle diverse materials, from delicate silks to heavy denims, with automatic tension adjustment ensuring optimal results across all fabric types. The incorporation of servo motors provides precise control over needle positioning and movement, resulting in superior stitch quality and reduced maintenance requirements. Industrial embroidery machines often feature large embroidery fields, allowing for designs up to 50 x 50 centimeters or larger, making them ideal for both small detailed work and large-format designs.