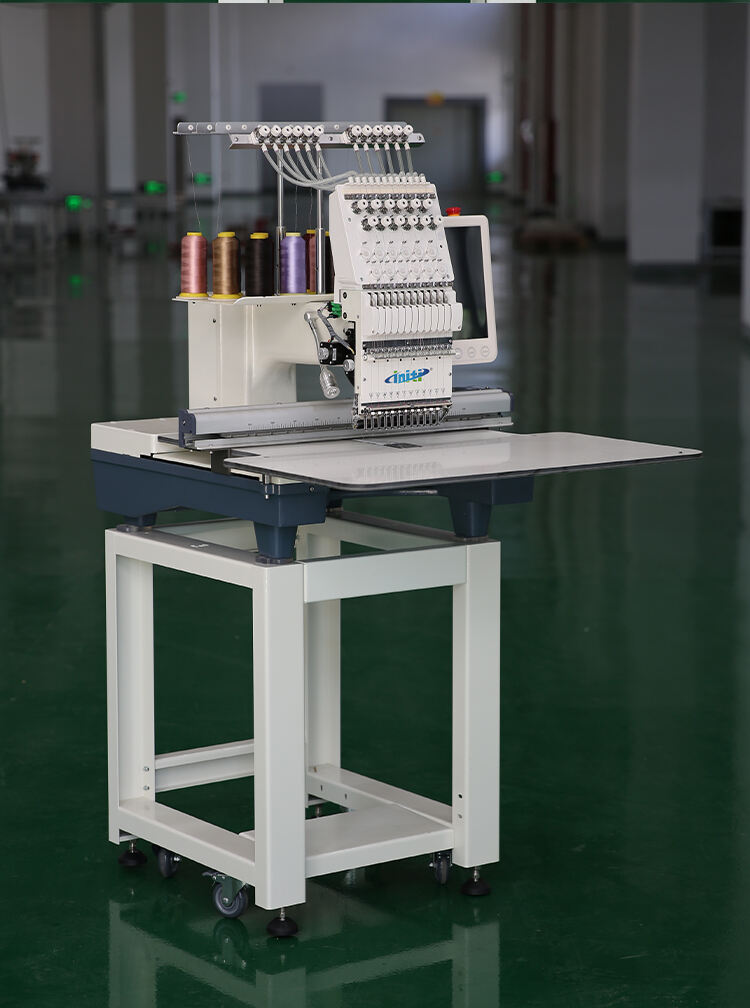

quality embroidery sewing machine

A quality embroidery sewing machine represents the pinnacle of modern textile craftsmanship, combining precision engineering with advanced digital technology. These sophisticated machines offer unprecedented versatility in creating intricate designs, from simple monograms to complex multi-color patterns. With built-in LCD touchscreens and user-friendly interfaces, these machines enable both beginners and professionals to achieve professional-grade results. They typically feature multiple needle positions, automatic thread cutting capabilities, and extensive built-in design libraries containing hundreds of patterns. The machines incorporate advanced tension control systems that maintain consistent stitch quality across different fabric types. Most models offer USB connectivity for importing custom designs and firmware updates, while some even provide wireless connectivity for direct design transfer. They come equipped with various hoop sizes, allowing for projects ranging from small patches to large decorative pieces. The automatic color-changing feature streamlines the embroidery process, while built-in sensors monitor thread tension and alert users to potential issues. These machines often include advanced features like automatic thread break detection, precise positioning systems, and memory capability for storing custom designs.