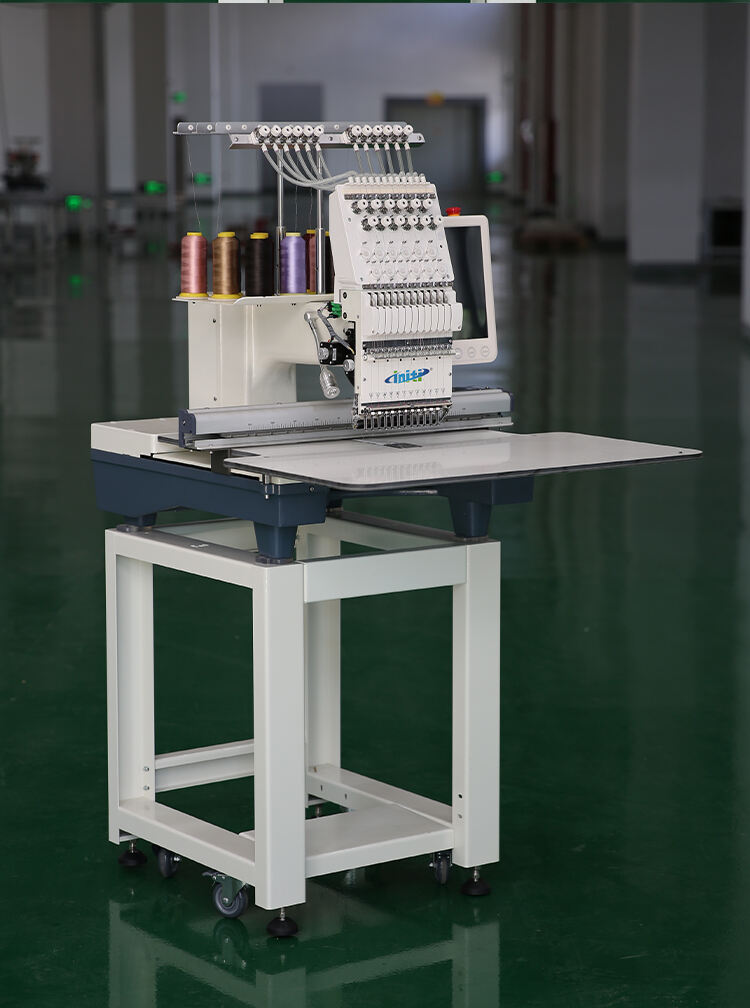

embroidery sewing machine factory

An embroidery sewing machine factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality embroidery equipment for both industrial and consumer markets. These facilities integrate advanced automation systems with precision engineering to create machines capable of intricate embroidery work. The factory employs cutting-edge production lines equipped with quality control stations, ensuring each machine meets stringent performance standards. The manufacturing process incorporates modern CNC technology, robotics, and automated assembly systems to maintain consistent product quality. These facilities typically feature specialized testing areas where machines undergo rigorous performance evaluations, testing stitch quality, tension control, and pattern accuracy. The factory's research and development department continuously works on innovative features, including improved thread handling systems, enhanced digitizing capabilities, and more efficient motor designs. Production areas are organized into distinct zones handling components manufacturing, assembly, electronic integration, and final testing. The facility also maintains dedicated spaces for software development, where teams work on creating and updating embroidery pattern programs and machine control systems. Environmental controls throughout the factory ensure optimal conditions for precise assembly and calibration of sensitive components. Quality assurance protocols are implemented at every stage, from raw material inspection to final product testing.