Understanding Single-Needle vs. Multi-Needle Embroidery Sewing Machines

Pros and Cons of Single-Needle Machines for Hobbyists

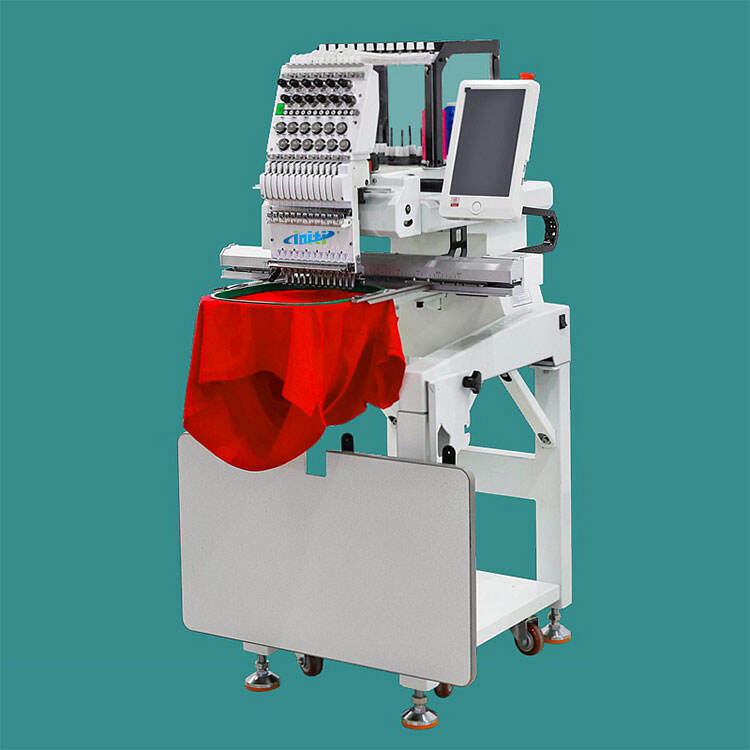

Many hobbyists love single needle embroidery machines because they don't cost much and are easy to figure out. These machines tend to be small enough to fit on most dressers or tables, so folks with tight spaces at home can still work on their projects. Beginners especially appreciate being able to get into embroidery without spending a fortune or needing a dedicated room for equipment. The downside? They just plain take longer to complete work compared to machines with multiple needles, so big projects will eat up more time than expected. Taking care of these machines isn't too bad either since there's only one needle involved, which makes learning the ropes a bit easier for newbies. But let's face it, single needle models struggle when it comes to switching colors frequently or tackling intricate patterns that require more attention to detail. For people who want to try embroidery with basic designs and aren't ready to invest heavily, these machines often make sense as a starting point.

When to Upgrade to Multi-Needle Commercial Models

Getting a multi needle embroidery machine really transforms things when trying to boost productivity and meet increasing customer demands. With these machines, several different colored threads can run at once which cuts down on stopping and changing threads manually something that makes all the difference for big scale work or serious embroidery projects. Features such as automatic thread cutting and quicker stitching speed definitely catch attention for anyone focused on getting stuff done fast. But there's no getting around it these machines cost more initially and take time to learn properly. For folks whose hobby has turned into a real business or anyone serious about making money from embroidery, investing in one might just pay off eventually. Sure nothing beats the speed and flexibility offered by multi needle models, though potential buyers need to think carefully about whether the price tag and learning curve are actually worth it for their particular situation.

Evaluating Hoop Size for Project Compatibility

Matching Hoop Dimensions to Common Embroidery Designs

Knowing standard hoop sizes matters when picking out an embroidery sewing machine that works well for different design requirements. Most hoops come in sizes ranging between 4 by 4 inches all the way up to 10 by 10 inches, and these measurements really affect what kind of projects someone might take on. Getting the right hoop makes a big difference in how good the final embroidery looks, especially since certain fabrics react differently depending on hoop size. Some special items like hats need specific cap hoops while things made from stretchy materials often call for tubular hoops instead. Before buying any embroidery machine though, spend some time looking at what kinds of designs people actually want to create. This helps prevent headaches later on when trying to fit complicated patterns into smaller hoops than intended.

Expandable Options for Large-Scale Creations

Many modern embroidery machines come with expandable hoops that let crafters work on bigger pieces without constantly switching between different sized hoops. When working with larger designs, having bigger hoops really cuts down on how often someone has to reset everything, which saves hours during long projects and reduces mistakes from misalignment. Machines that include multiple hoop sizes handle all sorts of creative needs, from small home decor items right up to bulk orders for businesses looking to produce custom embroidered goods. The best part is when machines have adjustable or completely interchangeable hoops built in. This kind of flexibility means hobbyists and professionals alike can keep upgrading their setup as their skills grow and project requirements change. For anyone serious about expanding their embroidery capabilities, checking out brands that actually sell extra hoops and specialized attachments makes sense. These additions transform basic machines into powerhouses capable of handling those ambitious large format embroidery jobs that would otherwise be impossible.

Essential Features for Efficient Embroidery Workflows

Stitch Speed and Precision Engineering

How fast a machine stitches matters a lot when looking at how efficient an embroidery sewing machine really is. Most models out there typically do between around 400 and up to 1000 stitches every minute. Faster stitching definitely cuts down on how long projects take to finish, but getting that right balance between speed and good engineering makes all the difference in keeping those stitches looking nice. Machines with fancy stuff like laser guides or super accurate motors work wonders for detailed designs where both quickness and exactness count. Newcomers might find themselves better off starting with something that runs at a slower pace while they get the hang of things. Reading what other people say online plus checking out test results from experts gives a much clearer picture of how well a particular machine actually performs in real life situations, helping anyone pick out the right embroidery sewing machine for their specific requirements.

Automatic Thread Cutters and Needle Threaders

Automatic thread cutters really boost productivity around the workshop by cutting down on all that tedious hand trimming work. And let's face it, who hasn't struggled with threading a needle? Needle threaders make this whole process so much easier, particularly helpful for folks dealing with arthritis or limited hand mobility. When shopping for a machine, check if it comes with good threading systems since poor ones just lead to tangled bobbins and ruined projects. The time saved alone is worth it, plus fewer mistakes means better looking stitches across the board. Most decent quality embroidery machines these days come packed with these handy features right out of the box. For anyone serious about embroidery, these little extras have become practically indispensable in today's market.

Touchscreen Interfaces for On-Machine Editing

Embroidery sewing machines with touchscreens let folks control everything right from the screen itself, making it simple to pick out designs and tweak settings without fumbling around with buttons. Most newer models have screen-based editing tools too, so crafters can adjust sizes, spin patterns around, or even tweak colors before they start stitching. The screens usually include helpful guides and quick fix tips for when things go wrong, which is great news for newcomers just getting started but also handy for seasoned stitchers who want to speed things up. Being able to see how changes look beforehand means less wasted fabric and fewer mistakes in the final product. When shopping around, take time to check what others say about how easy different interfaces are to use. A good touchscreen experience really makes all the difference when working on multiple projects at once or switching between complex designs.

Built-In Design Libraries vs. Custom Software Integration

Preloaded Patterns and Fonts for Immediate Creativity

A lot of embroidery sewing machines come with built in design libraries full of all sorts of patterns and fonts ready to go right out of the box. No need for extra software downloads or complicated setup processes. Pretty handy stuff actually. For folks just getting started with embroidery work or weekend crafters who want to keep things simple instead of dealing with fancy software packages, this built in stuff makes life much easier. When looking at machines though, it pays to check what kind of designs are included. Some have really good selections while others might leave something to be desired depending on what type of projects someone typically works on. What makes these machines even better? Well, many allow tweaks to the existing designs too. Want to adjust colors or scale up/down? That's possible on several models now. Makes sense when working on special occasion items or seasonal decorations where standard designs just won't cut it. This ability to personalize really expands what people can create with their machines.

USB/Wi-Fi Connectivity for External Design Importing

USB ports and Wi-Fi capabilities have become essential parts of modern embroidery sewing machines, especially for folks wanting to bring in their own custom designs from outside sources. Machines that handle various file types open up so much more creative potential since they aren't stuck relying just on whatever comes preloaded in the machine's memory. Transferring these digital designs wirelessly makes life so much easier for anyone working on complex projects, giving them way more freedom to experiment with different patterns and styles. Most newer models work really well with common design programs like Embird or Wilcom, which cuts down on frustration when trying to tweak things exactly how someone wants them. Considering how fast technology keeps evolving in the embroidery world, getting a machine with solid connectivity options isn't just convenient now but probably smart investment too if someone wants their equipment to stay relevant and flexible as trends change over time.

Balancing Budget with Long-Term Investment Value

Entry-Level vs. Commercial Machine Cost Analysis

The price gap between basic and professional embroidery machines matters a lot when picking the right one for specific needs. Most budget models fall somewhere between $200 and $800, great for folks who sew occasionally or are just getting started. Professional grade machines often jump past the $5,000 mark because they come packed with all sorts of bells and whistles that justify the higher price tag. Think about how often someone actually plans to use the machine and what kind of projects they want to tackle. For many hobbyists looking to grow their skills without breaking the bank, mid priced options strike a nice balance between decent quality and reasonable spending. Looking at what other people say about their experiences over time helps determine if something is worth investing in. Getting this info straight gives anyone trying to decide a clearer picture of what works best within their budget while still supporting their creative goals.

Warranty Considerations and Upgrade Flexibility

When getting an embroidery sewing machine, it really pays off to check out what kind of warranty comes with it plus any possible upgrades down the road. The truth is warranties differ quite a bit between different brands when looking at how long they last and exactly what they cover. Taking time to compare these things helps keep money spent on the machine from going to waste. Some companies actually run trade in deals or let folks upgrade within their own product line, something that makes sense if embroidery skills develop over time. Service agreements worth considering too since they often include regular maintenance checks which cuts down on unexpected breakdowns and keeps machines running smoothly for years. Getting clear on all this stuff about warranties and possible future improvements gives buyers real confidence about their choice. Knowing there's backup available frees up space in the creative process without worrying about equipment failures holding things back.

FAQ

What is the main difference between single-needle and multi-needle embroidery sewing machines?

Single-needle machines are often more affordable and suitable for beginners, while multi-needle machines offer enhanced productivity with capabilities for simultaneous use of multiple thread colors.

Are touchscreen interfaces necessary on embroidery sewing machines?

Touchscreen interfaces provide user-friendly controls for direct design editing on the machine, improving ease of use and efficiency, but might not be essential for all users.

Can I expand hoop sizes on embroidery sewing machines?

Some machines offer expandable hoop options, making them suitable for larger projects and reducing the need for frequent re-hooping.

How do connectivity features influence embroidery sewing machine usage?

USB or Wi-Fi connectivity allows users to import custom designs, providing greater flexibility and access to a broader range of patterns than built-in design libraries.