Core Capabilities of Modern Embroidery Sewing Machines

Automated Threading and Precision Stitching

Automatic threading in modern embroidery machines has really changed how people set things up. Setup times are now around 60-70% faster compared to older models, which makes a big difference for busy workshops. With all these buttons and switches doing the work automatically, operators can spend more time actually creating beautiful designs instead of fiddling with threads and tension settings. The machines also stitch with incredible accuracy these days. Crafters can produce those detailed floral patterns or complex geometric shapes that used to take hours of manual adjustment. What we see as a result are finished pieces that look professionally made, with clean edges and consistent color saturation throughout. This level of quality is exactly what customers expect when they pay premium prices for custom embroidered apparel or home decor items.

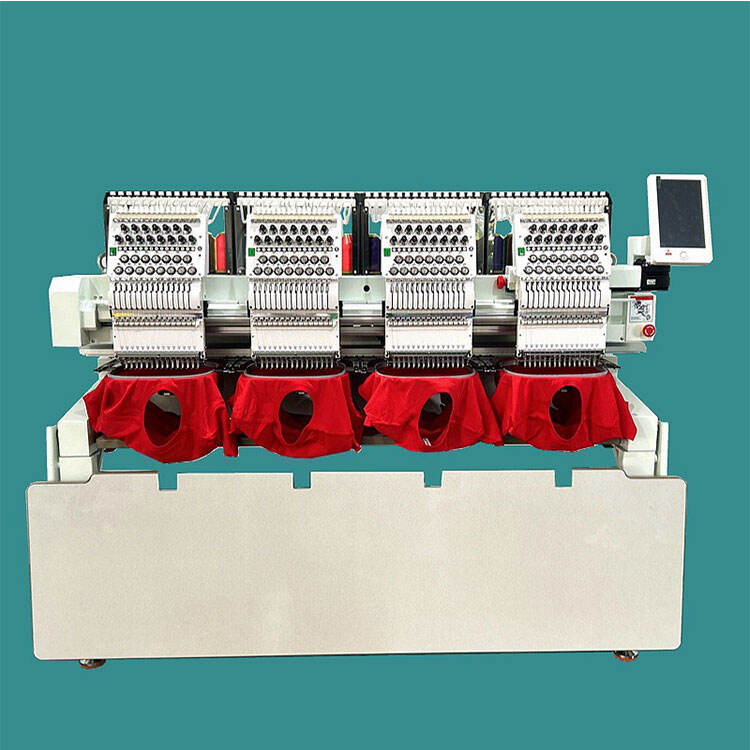

Multi-Hoop Systems for Complex Designs

Modern embroidery sewing machines now come equipped with multi hoop systems that let creators work on big, detailed designs without stopping or switching hoops mid-project. The fashion world keeps changing so fast these days, and having this kind of flexibility really matters when it comes time to stitch those complicated patterns quickly enough to meet deadlines. What makes multi hoop setups so valuable? They actually boost production speed quite a bit compared to older methods. For anyone doing custom work in apparel or brand merchandise, this means getting jobs done faster without sacrificing quality. Design studios and small business owners alike find themselves relying on this technology as they try to keep up with clients who want unique pieces but still expect turnaround times that match mass production standards.

Built-In Pattern Libraries and Digital Displays

Today's embroidery sewing machines have built-in pattern libraries that make designing much easier for crafters. Most models come loaded with hundreds of ready-to-use designs right from the factory, so people don't need to start from scratch every time they want something new. The pattern collections include everything from simple monograms to complex floral motifs, giving artists plenty of creative freedom without spending hours on customization. What really stands out though is the digital screen interface. These displays let sewists scroll through patterns, tweak stitch density, and adjust placement all while watching their creation take shape in real time. When combined with these onboard features, modern embroidery machines allow hobbyists and professionals alike to create detailed, high quality embroidered pieces without needing advanced technical skills.

Technological Innovations Driving the Industry

AI-Assisted Error Detection and Correction

Bringing AI into embroidery sewing machines represents a big step forward when it comes to spotting and fixing mistakes during the stitching process. These smart systems pick up on problems as they happen, automatically making adjustments so operators don't end up with expensive errors. Some research suggests that machines equipped with this kind of AI help boost product quality somewhere around 20% or so, which means faster work without sacrificing detail for companies looking to get better results. Beyond just saving money on wasted materials, these improvements make the whole embroidery operation much more dependable. Manufacturers now expect their machines to handle complex patterns consistently, something that was pretty difficult to achieve before these technological upgrades became available.

IoT Connectivity for Remote Design Uploads

Bringing IoT capabilities to embroidery sewing machines has completely changed how designs get uploaded and how production actually works on the factory floor. Companies now connect these machines to their systems so they can send out new patterns from anywhere, which cuts down on wasted time and makes teamwork possible even when people are spread across different cities. The efficiency boost from having IoT in place means designers don't have to wait around for approvals anymore while production staff can keep things moving without constant back and forth. What does this mean practically? Faster turnaround times for custom orders and better responsiveness to what customers want right now in the marketplace. Factories that adopted this tech report being able to handle rush jobs that used to take weeks in just days instead.

Energy-Efficient Motors and Sustainable Practices

These days, many embroidery machines come standard with energy saving motors that really bring down electricity usage. For shop owners, this means lower bills at the end of the month plus meeting what customers want these days green manufacturing options. The textile industry has been pushing toward sustainability for years now, so manufacturers who switch to these efficient models can offer environmentally friendly embroidery work without any loss in quality. Plus, when companies adopt these practices, they tackle environmental issues head on while making their products more attractive to the growing segment of shoppers who care about where and how things are made.

Creative Applications Across Industries

Personalized Fashion and Custom Apparel

Personalized fashion is changing how we think about clothes, and embroidery machines are really driving this trend forward. These machines let designers add all sorts of custom touches to garments, making each piece truly one-of-a kind. People want something different these days, not just mass produced stuff. Recent surveys found around 7 out of 10 shoppers actually look for items they can personalize when shopping for new clothes. We're seeing more embroidered pieces hit store shelves because brands understand what customers want now. When companies offer customization options, they build stronger connections with their audience while standing out from competitors who stick to standard designs.

Decorative Home Textiles and Interior Design

Embroidery machines have really changed how we make decorative home textiles, making it easier than ever to create beautiful interior designs. These days, tablecloths, drapes, and even pillow covers often come with detailed embroidery work that adds class and personality to any room. Interior designers are noticing this shift too, since people want more handmade touches in their spaces. Demand for embroidered fabrics has gone up quite a bit lately. We're seeing this reflected in the growing popularity of custom home decor options. Homeowners and decorators both seem drawn to pieces that tell a story about who lives there, rather than just mass-produced items off the shelf.

Branded Corporate Merchandise Production

Embroidery sewing machines make a real difference in corporate merchandise production, giving branded items that clean, professional look everyone wants. Companies often use embroidery on uniforms, caps, and all sorts of promotional stuff to keep their branding looking sharp across different products. Some studies have found that good quality branded merchandise can boost brand awareness around 80% give or take. That makes sense when we think about how people remember logos they see regularly. Adding embroidery to product lines helps businesses connect better with customers too. When someone gets a nicely made embroidered item, it just feels more trustworthy somehow. The craftsmanship speaks volumes about what kind of company would put that much care into something as simple as a hat or t-shirt.

Choosing the Right Machine for Your Needs

Evaluating Stitch Speed and Embroidery Field Size

Picking out an embroidery machine requires looking at two main factors: how fast it can stitch and how big its embroidery area actually is. The stitch speed makes a real difference in getting work done quickly, and today's machines can go as high as 1,000 stitches every single minute. That kind of speed matters a lot when someone needs to finish orders before a deadline hits. Then there's the question of embroidery field size. This basically tells what size projects are possible. Bigger areas mean room for more complex designs, something that matters greatly in industries like making custom t-shirts or sportswear. When shopping around, focus on finding machines where these specs match what actual jobs will require. Some folks might need super detailed small work while others deal with bigger pieces, so matching equipment to real world needs saves time and frustration down the road.

Software Compatibility and Design Flexibility

When looking at embroidery sewing machines, software compatibility and how flexible they are with designs really matters for getting the most out of them. Machines that work smoothly with standard design software let creators customize their work better and scale up production when needed. Most modern embroidery systems can run with different software packages, giving designers the freedom to adjust complex details without too much hassle. Good software integration means artists stay creative while businesses stay ahead of the curve since they can keep up with what's popular in design right now. A machine that plays nice with various software options makes all the difference when tackling different kinds of projects and client requests.

Comparing Industrial vs. Home-Use Models

Knowing what separates industrial from home embroidery machines matters a lot when picking out equipment that actually works for what needs doing. Industrial grade machines handle big production runs thanks to their heavy duty build quality and extra features needed for mass manufacturing. Many come with multiple needles installed already and stitch at lightning speed, making them go-to choices for shops running real business operations. Home models take a different approach altogether. They're built for people just getting started with embroidery or folks who treat it as weekend fun project. These machines focus more on ease of use and keeping costs down without breaking the bank. The key thing remains matching specs to actual requirements though. Someone trying to run a profitable embroidery venture would struggle badly with a basic home model while serious hobbyists might find industrial units way too complicated and expensive for simple decorative work around the house.

Future Trends in Embroidery Technology

3D Texture Creation with Hybrid Stitching

Embroidery tech is moving in exciting new directions these days, especially when it comes to creating those cool 3D textures through what's called hybrid stitching. Basically, this means mixing up old school embroidery techniques with all sorts of modern tools and materials. The result? Surface designs that pop off the fabric with real depth and dimension. When artists play around with various stitches and fabrics together, they end up making things that feel amazing to touch as well as look at. What makes hybrid stitching so interesting is how it opens doors for totally new creative expressions. Designers aren't just sticking to what's been done before anymore. They're experimenting with shapes and textures we never saw in traditional embroidery, crafting pieces that really stand out and match what they want to express artistically.

Augmented Reality for Design Preview

AR tools are changing the game for embroidery work, giving designers a chance to see exactly what their creations will look like on final products right away. With this tech, both creators and potential buyers get to check out embroidered designs at their real sizes and positions on garments or other items. These AR applications actually make people happier with their purchases since there's much less chance of mistakes happening. When something doesn't look quite right, changes happen fast before anyone starts stitching anything together. The whole process works like this: quick checks lead to better results because what gets produced matches what was originally imagined. Plus, fewer mistakes mean less wasted fabric and thread, which is good news all around for anyone involved in embroidery projects big or small.

Blockchain Integration for Pattern Authentication

More and more embroidery artists are starting to use blockchain tech in their design workflows to make sure patterns stay authentic and aren't copied illegally. When they put their work on the blockchain, it creates a permanent record that proves who made what when. This helps solve those annoying IP issues we all face these days. Designers get recognized properly because every stitch has a digital fingerprint attached to it. What's really cool about this setup is that both makers and buyers feel safer knowing there's a tamper-proof ledger tracking everything. Embroidery creators can share their stuff online or sell through marketplaces without constantly worrying someone will steal their designs and pass them off as original work.

Maintenance and Skill Development

Routine Care for Optimal Machine Longevity

Keeping an embroidery sewing machine running smoothly requires regular care and attention. Cleaning out lint buildup from the bobbin area and applying proper lubricant to moving parts helps these machines last much longer than they otherwise would. Most technicians agree that following some kind of maintenance plan makes sense, especially since well maintained machines tend to run better for many more years. Taking time for routine upkeep means fewer breakdowns later on and saves money in repair costs over time. The investment pays off both in terms of reliability and avoiding unexpected expenses when something goes wrong unexpectedly.

Mastering Advanced Digitizing Software

For anyone serious about embroidery work, getting comfortable with advanced digitizing software makes all the difference when it comes to standing out among other designers. Once someone gets the hang of working through these complicated programs, they start producing much more detailed and high quality embroidery projects than before. Plenty of options exist for those wanting to improve their skills too. Online courses, YouTube videos, even local classes at craft stores help fill in the gaps between what beginners know and where professionals operate. Keep practicing with different tools and techniques actually leads to some pretty amazing design outcomes that would have seemed impossible just months earlier.

Joining Maker Communities for Technique Sharing

Getting involved in maker groups provides great chances to meet people and swap tips about embroidery techniques. These groups are basically hubs where folks share what they know and pass around supplies, creating spaces where hobbyists pick up tricks from each other all the time. Many of these communities run regular workshops covering everything from basic stitching to advanced decorative methods, which helps keep everyone motivated and learning new skills. Joining in means tapping into years worth of combined expertise that really makes a difference in improving one's work over time.

FAQ

What are the core capabilities of modern embroidery sewing machines?

Modern embroidery sewing machines offer automated threading, precision stitching, multi-hoop systems for complex designs, built-in pattern libraries, and digital displays.

How does AI technology benefit embroidery sewing machines?

AI technology assists in error detection and correction, ensuring real-time identification of stitching mistakes and automatic corrections, thereby improving output quality and minimizing waste.

What is the importance of IoT connectivity in embroidery sewing machines?

IoT connectivity allows for remote design uploads and management, streamlining workflows and enabling collaboration across multiple locations, thus enhancing productivity.

How do energy-efficient motors contribute to sustainability?

Energy-efficient motors reduce power consumption and operational costs while aligning with the demand for eco-friendly manufacturing practices, supporting greener embroidery solutions.

What should I consider when choosing an embroidery sewing machine?

Consider the machine's stitch speed, embroidery field size, software compatibility, design flexibility, and whether it suits industrial or home use. These factors ensure it meets your project requirements.

Table of Contents

- Core Capabilities of Modern Embroidery Sewing Machines

- Technological Innovations Driving the Industry

- Creative Applications Across Industries

- Choosing the Right Machine for Your Needs

- Future Trends in Embroidery Technology

- Maintenance and Skill Development

-

FAQ

- What are the core capabilities of modern embroidery sewing machines?

- How does AI technology benefit embroidery sewing machines?

- What is the importance of IoT connectivity in embroidery sewing machines?

- How do energy-efficient motors contribute to sustainability?

- What should I consider when choosing an embroidery sewing machine?