A detailed analysis of the structural, technological, and application differences between the two machine types

In the embroidery-machine market, cap embroidery and flat embroidery are often mentioned side by side, yet few resources systematically list their concrete differences in mechanical structure, production flow, and maintenance cost. Many first-time buyers are surprised by the cylindrical cap frame and tilted head of a cap embroidery machine, while the large worktable and multi-head arrays of a flat embroidery machine can be equally striking. Which type is truly suited to your order mix? Do you realize that the same design file needs extra pull compensation on a cap embroidery machine, whereas a flat embroidery machine can run the original file without modification? This article uses questions and side-by-side comparisons to break down every difference, helping you achieve the best balance among budget, capacity, and maintenance intervals.

Mechanical structure and space layout

Cylindrical drive system in cap embroidery machines

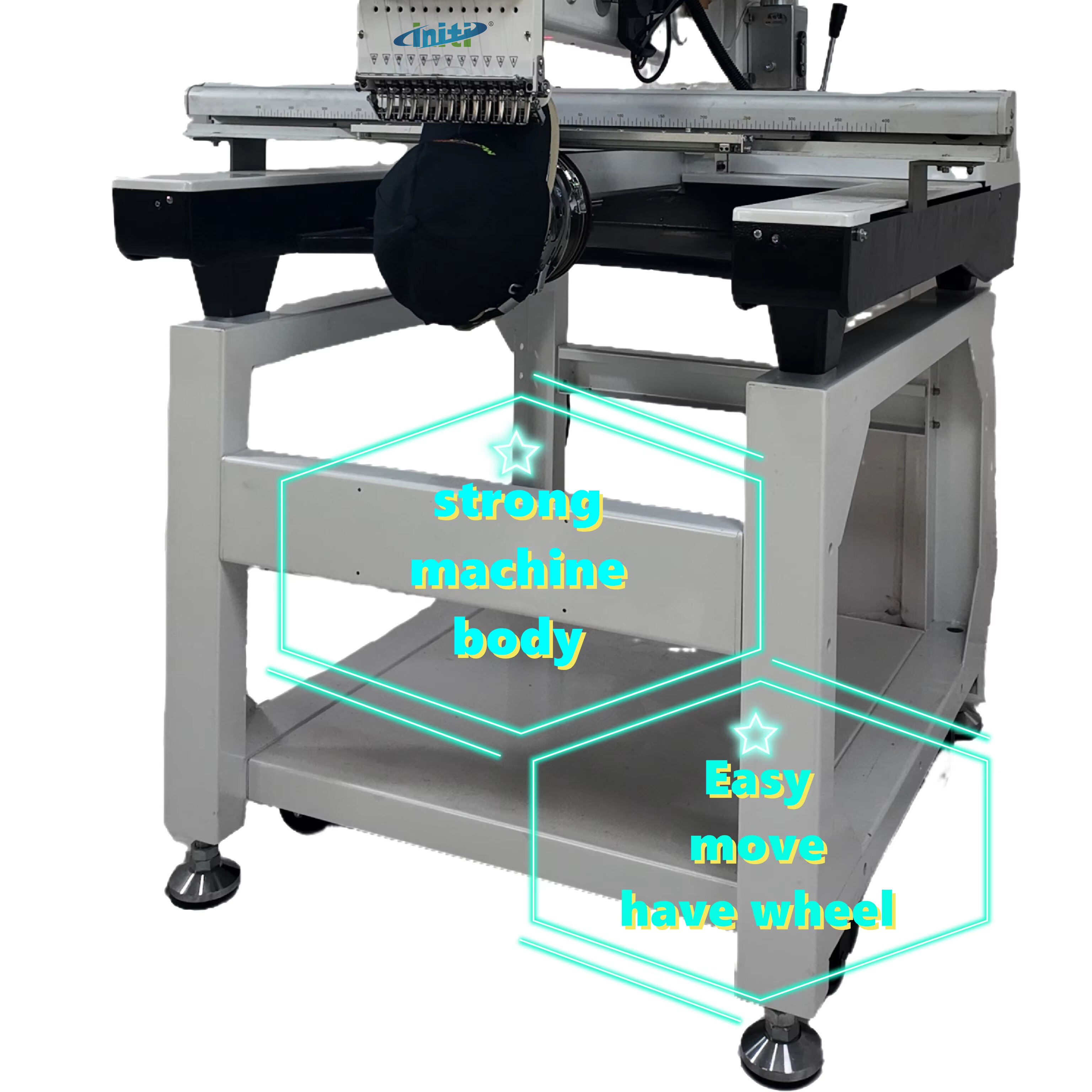

Cap embroidery machines combine a cylindrical cap frame with an inclined head set at 30°–45° to the horizontal plane, allowing the curved front panel of a cap to sit naturally in the sewing field. A servo motor rotates the cap frame so every stitch lands on the same arc. Are you worried that a conventional flat embroidery machine cannot hold a curved surface securely? Built-in tension-compensation algorithms monitor frame angle in real time and fine-tune stitch length to prevent distortion between the crown’s peak and brim. The compact footprint is only 70 % of an equivalent-head-count flat embroidery machine, saving precious floor space for small studios.

Flat cross-beam and multi-head scalability in flat embroidery machines

Flat embroidery machines rely on a flat cross-beam; the pantograph moves in the X-Y plane at high speed, ideal for large fabric panels, cut garment pieces, and home-textile items. Four to twenty individual heads can be mounted side by side under the same beam, all sharing the same drive command for simultaneous output. Do you need to process different sizes of T-shirt fronts in the same batch? An ultra-wide 1 200 × 500 mm table allows continuous work without re-hooping. The modular design supports future head additions—just plug an expansion board into the control cabinet—shortening the return-on-investment cycle.

Flat embroidery machines rely on a flat cross-beam; the pantograph moves in the X-Y plane at high speed, ideal for large fabric panels, cut garment pieces, and home-textile items. Four to twenty individual heads can be mounted side by side under the same beam, all sharing the same drive command for simultaneous output. Do you need to process different sizes of T-shirt fronts in the same batch? An ultra-wide 1 200 × 500 mm table allows continuous work without re-hooping. The modular design supports future head additions—just plug an expansion board into the control cabinet—shortening the return-on-investment cycle.

Fixture and frame systems

Curved locking of dedicated cap frames

The core fixture of a cap embroidery machine is a 360° adjustable cap frame with metal claws evenly distributed along the crown curve, securing front, side, and back panels. Have you ever seen a side-panel logo skewed by uneven tension? High-end cap embroidery machines add magnetic side clamps that snap onto the visor, preventing fabric creep during stitching. Interchangeable silicone pads of different hardness adapt to baseball caps, trucker caps, or bucket hats, cutting change-over downtime to minutes.

Universal frames and vacuum hold-down on flat embroidery machines

Flat embroidery machines use universal flat frames—spring clips or hook-and-loop strips secure fabric—and are compatible with T-shirts, hoodies, jackets, and pillow covers. For lightweight textiles, an optional vacuum table uses negative pressure to lock the material flat, preventing wrinkles during high-speed movement. Are you afraid large panels will shift? Zoned vacuum control activates suction only under the active sewing head, saving energy and reducing noise. Laser-edge positioning bars display frame boundaries in real time, letting operators align designs quickly.

Digitizing and design differences

Curved-surface compensation in cap embroidery

Because a cap surface is three-dimensional, cap embroidery machines require curved-surface compensation in digitizing. The software automatically reduces density by 3 %–5 % at the edges to prevent puckering at the crown’s peak. Do you notice that the same logo appears narrower on a cap than on a flat sample? The human eye compresses curved visuals; smart compensation widens the horizontal proportion to keep the finished cap matching the flat artwork. Premium models offer one-click templates for baseball or trucker styles, eliminating manual parameter tweaks.

h3 Flat freedom for flat embroidery

Flat embroidery faces a completely flat surface, so no arc correction is needed. Designers can apply dense satin stitches and complex fills without restriction. Want large-scale gradients? Flat embroidery machines support 1 200 rpm fill speeds and gradient threads for subtle color transitions. Built-in “oversize splitting” automatically segments patterns wider than the machine’s field and adds alignment marks for precise rejoining. For symmetrical garment fronts, the machine can mirror-copy designs without re-digitizing.

Flat embroidery faces a completely flat surface, so no arc correction is needed. Designers can apply dense satin stitches and complex fills without restriction. Want large-scale gradients? Flat embroidery machines support 1 200 rpm fill speeds and gradient threads for subtle color transitions. Built-in “oversize splitting” automatically segments patterns wider than the machine’s field and adds alignment marks for precise rejoining. For symmetrical garment fronts, the machine can mirror-copy designs without re-digitizing.

Production efficiency and order changeover

Single-cap cycle times and batch rhythm

Cap embroidery machines require caps to be loaded one by one; a single piece cycle ranges from 3–8 minutes depending on stitch count and color changes. Have you calculated how long 100 small-logo baseball caps will take? A single-head cap embroidery machine averaging five minutes per cap produces 96 pieces in an eight-hour shift. Upgrading to a dual-head cap embroidery machine doubles output while increasing floor space by only 30 %. Style changeover requires swapping silicone pads and magnetic clamps—done in under three minutes.

Continuous runs and long-order advantages of flat embroidery

Flat embroidery machines can run continuous fabric; one loading can embroider dozens of T-shirt fronts. Expecting a 1 000-piece hoodie order? A twelve-head flat embroidery machine working twelve fronts simultaneously outputs two finished pieces per minute, totaling 960 garments in eight hours. For color-intensive long runs, an automatic color-change tower handles up to fifteen spools, reducing manual intervention. Style changes are seamless—just load a new design file and the machine keeps running without stopping.

Maintenance costs and failure rates

Tilt-mechanism care in cap embroidery

The angled head and cylindrical rails of a cap embroidery machine need special grease every 200 operating hours to prevent metal wear that can shift angle accuracy. Noticing head vibration that affects curved stitches? Periodic servo encoder calibration keeps deviation within 0.1 mm. Thanks to a compact layout, cleaning requires only removing the front cover—maintenance time is 50 % shorter than for flat embroidery machines.

Beam and multi-head synchronization in flat embroidery

Flat embroidery cross-beams and linear guides need a full cleaning every 500 hours to prevent lint build-up that can harm synchronization. Multi-head models feature automatic diagnostics that monitor current and temperature in real time, issuing early failure alerts. Worried that one head failure will stop the entire line? Modular motor design supports hot-swapping a single head in under five minutes, letting the remaining heads continue with near-zero downtime.

Price ranges and return on investment

Entry-level cap embroidery budgets and upgrade paths

Single-head cap embroidery machines sit price-wise between flat single-head and multi-head machines, yet their niche focus yields higher resale value. Concerned about upfront cost? Choose a model that supports adding a second head later—no need to replace the main unit when orders grow. Some brands offer zero-interest financing with a 30 % down payment, easing cash-flow pressure.

High-output returns from flat multi-head machines

Flat multi-head machines cost more upfront, but on a per-head basis the price can be lower than entry cap embroidery machines. Have you calculated the ROI? A twelve-head model produces three times the daily value of a single-head flat machine, shortening payback to under ten months. Remote diagnostics from the manufacturer reduce on-site service trips, further cutting operating costs.

Flat multi-head machines cost more upfront, but on a per-head basis the price can be lower than entry cap embroidery machines. Have you calculated the ROI? A twelve-head model produces three times the daily value of a single-head flat machine, shortening payback to under ten months. Remote diagnostics from the manufacturer reduce on-site service trips, further cutting operating costs.

FAQ

Can a cap embroidery machine be converted into a dual-purpose flat model

Yes. Some brands supply interchangeable frame kits—remove the cap frame and install a flat table in about fifteen minutes, achieving dual use with one machine.

Do flat embroidery machines support cap embroidery add-ons

Select high-end flat embroidery machines offer cap attachments, but beam geometry limits curvature compatibility compared with dedicated cap embroidery machines, making them suitable only for occasional small-batch cap jobs.

Select high-end flat embroidery machines offer cap attachments, but beam geometry limits curvature compatibility compared with dedicated cap embroidery machines, making them suitable only for occasional small-batch cap jobs.

Which machine is better for a start-up studio

If the main orders are cap-related, start with a single-head cap embroidery machine for small footprint and quick payback. If T-shirts and hoodies dominate, choose a flat embroidery machine and scale rapidly with additional heads.

If the main orders are cap-related, start with a single-head cap embroidery machine for small footprint and quick payback. If T-shirts and hoodies dominate, choose a flat embroidery machine and scale rapidly with additional heads.

How do maintenance intervals affect labor costs

Cap embroidery machines need service every 200 hours and can be handled by one person. Flat multi-head machines need multi-person cleaning every 500 hours, but automated diagnostics cut failure rates, so overall labor impact is minimal.

Cap embroidery machines need service every 200 hours and can be handled by one person. Flat multi-head machines need multi-person cleaning every 500 hours, but automated diagnostics cut failure rates, so overall labor impact is minimal.

Table of Contents

- A detailed analysis of the structural, technological, and application differences between the two machine types

- Mechanical structure and space layout

- Fixture and frame systems

- Digitizing and design differences

- Production efficiency and order changeover

- Maintenance costs and failure rates

- Price ranges and return on investment

- FAQ