Предимството на машината за търговско избродиране през 2025 г.

Провеждането на печеливш бизнес в сферата на избродирането през 2025 г. зависи по-малко от художествен талант и повече от механична надеждност, скорост и прозрачност на данните. Една машина за избродиране с множество игли става двигател, който превръща конеца и тъканта в печалба, но само когато всяка спецификация съответства на реалните производствени изисквания. Собствениците на студио често питат дали една машина за бродиране може да обработва шапки, плоски предмети, ръкави и торби, без постоянно преопределяне на конеца. Краткият отговор е да, при условие че машината за бродиране разполага с достатъчно висок брой игли, интелигентно сортиране по цвят и система от рамки, която може да се адаптира в движение. Тази статия представя критериите, които правят разграничението между оборудване за хоби и истинска търговска машина за бродиране, оценява водещите конфигурации, налични днес, и предлага практични насоки относно бюджетното планиране, поддръжката и осигуряването за бъдещето. В края на краищата, изразът машина за бродиране ще ви се стори по-малко като маркетингов жаргон и повече като стратегически партньор в ежедневните операции.

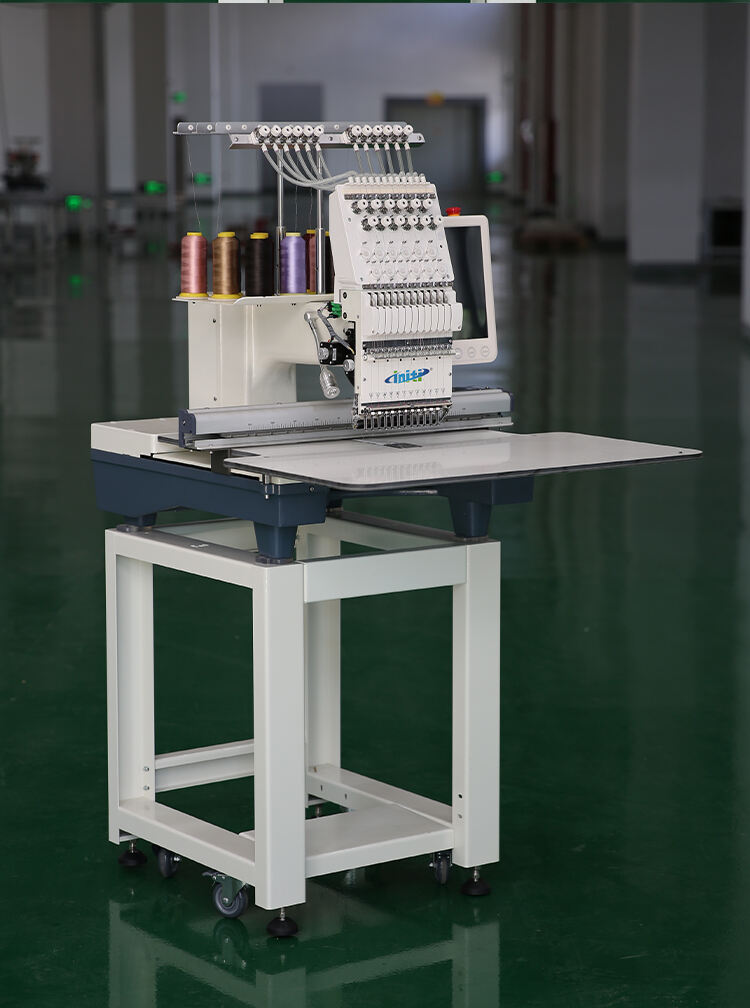

Основни спецификации, които определят търговска многоиглена машина за бродиране

Брой игли и гъвкавост по отношам на цветовете

Машината за бродиране предлага ли десет, дванадесет или петнадесет игли? Десет игли са подходящи за повечето палитри с корпоративни лога, но при петнадесет игли няма нужда да спирате по средата на процеса и да сменяте шпулите, когато клиентът настоява за дизайн в дванадесет цвята. Повече игли също намаляват загубите от конец, защото машината вече не изрязва и преначева многократно един и същ цвят. Въртяща се стойка за конеца, която поддържа конусите във вертикално положение, предотвратява заплитането при висока скорост. Автоматичен сензор за обрив на конеца на всяка позиция на иглата предотвратява т.нар. 'призрачно шиене', което е необратимо поврежда скъпите изделия.

Поле за бродиране и съвместимост с рамки

Търговски поръчки пристигат във всяка форма, а равни продукти рядко надвишават 400 мм ширина, но пък капачките изискват цилиндрични рамки за движение, а гърбовете на якета се нуждаят от масивни тръбни обръчи. Машината за бродерия трябва да превключва между тези формати за минути, без да се налага повторна калибрация на началните точки. Функцията с лазерно проследяване проектира точния контур върху платът преди първия шев, осигурявайки, че машината за бродерия ще започне от правилното място, дори и върху тъмни дрехи. Попитайте дали производителят осигурява магнитни бързодействащи скоби; те намаляват времето за монтиране наполовина и предпазват деликатните платове от увреждане при хване.

Скорост, стабилност и серво управление

Скоростните класификации на хартия може да подведат. Търговска машина за бродиране може да твърди 1200 шева в минута, но вибрациите при тази скорост могат да изкривят регистрацията при гъсти запълвания. Двойни серво мотори по осите X и Y, комбинирани с греда от лити алуминий, поддържат машината за бродиране стабилна при скорости над 1000 ш/мин. Уверете се, че контролната клавиатура предлага стъпаловидно регулиране на скоростта, така че операторите да могат да забавят машината по време на участъци с метална нишка, без да пренаписват целия дизайн файл.

Най-добри конфигурации с множество игли за високопроизводителни работни процеси

Дванадесет-неутрална компактна работна лошадка

Тази машина за бродиране побира дванадесет игли в пространство по-малко от стандартна врата, което я прави идеален избор за търговски обекти с ограничено пространство. Доставя се с четири комплекта рамки, включително капаче за шапки и плоска маса с размери 360 × 200 мм. Въпреки малките си размери, машината за бродиране осигурява 1 000 шева в минута при дванадесетчасов работен ден и може да съхранява 100 милиона шева в паметта си. Потребителите съобщават за средно дневен изход от 600 емблеми на гърдите отляво върху пола-ризните без прегряване.

Петнадесетиглена високоскоростна флагманска машина

Създадена за центрове за изпълнение на поръчки, тази машина за бродиране комбинира петнадесет игли с сервоелектродвигател с мощност 1 200 шева в минута. Система за бърза смяна на роторни кламери позволява на техник да смени кламерите за деветдесет секунди, без да се налага премахването на дрехата от рамката. Интегрираното облачно наблюдение изпраща графики за ефективност на телефона на производствения ръководител, така че всяка машина за бродиране в парка може да бъде планирана за профилактичен сервиз преди настъпване на простои.

Двуглава машина с двадесет и четири игли

Когато поръчките надвишават 5 000 броя седмично, две синхронизирани емблемни машини с общ контролен шкаф значително намаляват разходите за труд. Всяка глава работи независимо, така че докато едната обработва капи, другата може да работи по гърбовете на якета. Общият сензорен екран зарежда дизайни към двете глави едновременно, а ако едната машина за емблеми спре поради скъсване на конец, другата продължава работа без прекъсване.

Функции на софтуера и автоматизацията, които намаляват трудовите разходи

Автоматична сортировка по цвят и отрязване на скоковите стегове

Съвременните софтуерни решения за цифровизиране експортират файлове, които точно определят кога машината трябва да отреже конеца и кога да премине към следващата операция. Най-добрите системи изчисляват най-краткия път между блоковете от различни цветове, намалявайки отрязванията на конеца с до тридесет процента. По-малко отрязване означава по-малко ръчна обработка, което дава възможност машината за емблеми да прекарва повече време в генериране на приходи.

Управление на файлове чрез облачни технологии

Представете си, че получавате модифициран лого в 21:00 ч. и до 21:05 ч. всички машина за бродиране в магазина са обновени. Облачните платформи изпращат DST или PES файлове директно към машината за бродиране чрез Wi-Fi. Контролът на версиите предотвратява операторите случайно да използват остаряло изкуство, а дистанционната диагностика намалява на 50% необходимостта от сервизни извиквания на място.

Вградена камера за проверка на позиционирането

Камера, монтирана отгоре, сканира всяка дреха преди шиене, като сравнява контура с файла на дизайна. Ако машината за бродиране открие отклонение, причинено от неравномерно опъване, тя автоматично коригира началната точка. Само тази функция предотвратява скъпи загуби при бродиране на скъпи дрехи, които се продават по петдесет долара парче.

Стратегии за поддръжка, удължаващи живота на машината за бродиране

Ежедневни проверки за смазване

Всяка промишлена машина за бродиране се доставя с визуално стъкло на главата и фелтена мушка под ротационната кука. Операторите трябва да проверяват нивото на маслото при стартиране и да добавят два милилитра, ако индикаторът е под червената линия. Пропускането на този тридесетсекунден ритуал може да доведе до закляване на куката и четиричасов интервал за ремонт.

Ежеседмична калибрация и проверка на натягането

Регулаторите за натягане могат да се разминават след хиляди шевове. Прост тестов модел от колони с атлазен шев с различни дължини показва дали машината за бродиране балансира правилно горната и долната нишки. Калибрирайте веднъж седмично и записвайте измерванията; анализът на тези данни предвижда кога ще е необходим пълния сервизен преглед.

График за годишна смяна на части

Дори и най-добрата машина за бродиране изисква разходни материали. Планирайте да заменяте ротационните куки на всеки двадесет милиона бода, зъбните колани на всеки две години и резервните батерии на основната платка на всеки три години. Закупуването на тези продукти на внос намалява цената на единица с двадесет процента и осигурява непрекъснатата работа на парка от машини за бродиране по време на високия сезон.

Бюджетиране и изчисляване на възвръщаемостта при закупуване на комерсиални машини за бродиране

Първоначални инвестиции срещу лизингови опции

Заплащането на машина за бродиране в брой избягва лихвените разходи, но блокира ликвидността. Лизингът разпределя разходите в рамките на тридесет и шест месеца и често включва сервизни посещения, но общите разходи могат да надвишат покупната цена с петнадесет процента. Сравнете двата сценария, като използвате прогнозното дневно производство на машината за бродиране и средната продажна цена на хиляда бода.

Скрити разходи при инсталацията и обучението

Превозът на машина за многоглаво бродиране може да надхвърли хиляда долара, особено ако е необходима доставка с вдигаща платформа. Предвидете два дни за инсталация от техник и обучение на оператора; простоюването по време на стартирането може да изтрие ранните печалби. Попитайте дали доставчикът на машината за бродиране предлага дистанционно въвеждане в експлоатация, за да се минимизират разходите за пътуване.

Времеви период за връщане на инвестицията въз основа на реални поръчки

Да предположим, че машина за бродиране с петнадесет игли струва двадесет и пет хиляди долара и произвежда хиляда емблеми на лявата страна на гърдите на ден по четири долара всяка. След като се извадят разходите за конци, труд и общо разпределение, нетната печалба на емблема е два долара. Машината за бродиране си връща цената за сто двадесет и пет работни дни, или приблизително шест месеца. По-бързото изпълнение на спешни поръчки може да съкрати този период до деветдесет дни.

Осигуряване на инвестицията в машина за бродиране за бъдещето

Модулни пътеки за ъпгрейд

Технологиите се развиват бързо, но механичните рамки издръжат десетилетия. Изберете марка за машина за бродиране, която предлага комплект за модернизация за нови глави, по-големи обръчи или лазерни мостови адаптери. Модулната архитектура защитава първоначалните инвестиции в машина за бродиране, докато постепенно добавя нови функции.

Енергийна ефективност и устойчивост

Комуналните такси нарастват всяка година. Новите серво двигатели намаляват консумацията на енергия в режим на изчакване с шестдесет процента в сравнение със стъпаловидни системи. Попитайте дали машината за бродиране отговаря на изискванията за местни отстъпки за енергийна ефективност и дали производителят изкупува стари рамки при обмяна.

ЧЗВ

Колко игли наистина са необходими на търговска машина за бродиране

Повечето работилници процъфтяват с дванадесет игли, но с петнадесет игли се избягва простоите, когато клиентите поискат сложни цветови палитри. Оценете средната си цветова палитра, преди да изберете броя на иглите на машината за бродиране.

Какви размери обръчи трябва да са стандартни за многобройна машина за бродиране

Очаквайте най-малко плосък хoop с размери 360 × 200 mm, държач за шапки и рамка за гърба на яке. Проверете дали допълнителни специализирани хoops са налични за модела на машина за бродиране, който избирате.

Може ли една машина за бродиране да обработва шапки и плоски изделия в един и същи работен смени

Да, при условие че машината за бродиране разполага с бързозаменяема система за държачи и лазерно позициониране. Операторите могат да превключват между форматите за по-малко от три минути, без да се налага повторна калибрация на началните точки.

Колко години обикновено служи търговска машина за бродиране

При правилно поддържане, механичният рама служи повече от петнадесет години. Електронните компоненти може да се наложи да бъдат подменени след осем до десет години, но модулният дизайн позволява модернизация на платката на машината за бродиране, без да се заменя цялата единица.

Съдържание

- Предимството на машината за търговско избродиране през 2025 г.

- Основни спецификации, които определят търговска многоиглена машина за бродиране

- Най-добри конфигурации с множество игли за високопроизводителни работни процеси

- Функции на софтуера и автоматизацията, които намаляват трудовите разходи

- Стратегии за поддръжка, удължаващи живота на машината за бродиране

- Бюджетиране и изчисляване на възвръщаемостта при закупуване на комерсиални машини за бродиране

- Осигуряване на инвестицията в машина за бродиране за бъдещето

- ЧЗВ