high quality custom embroidery machine

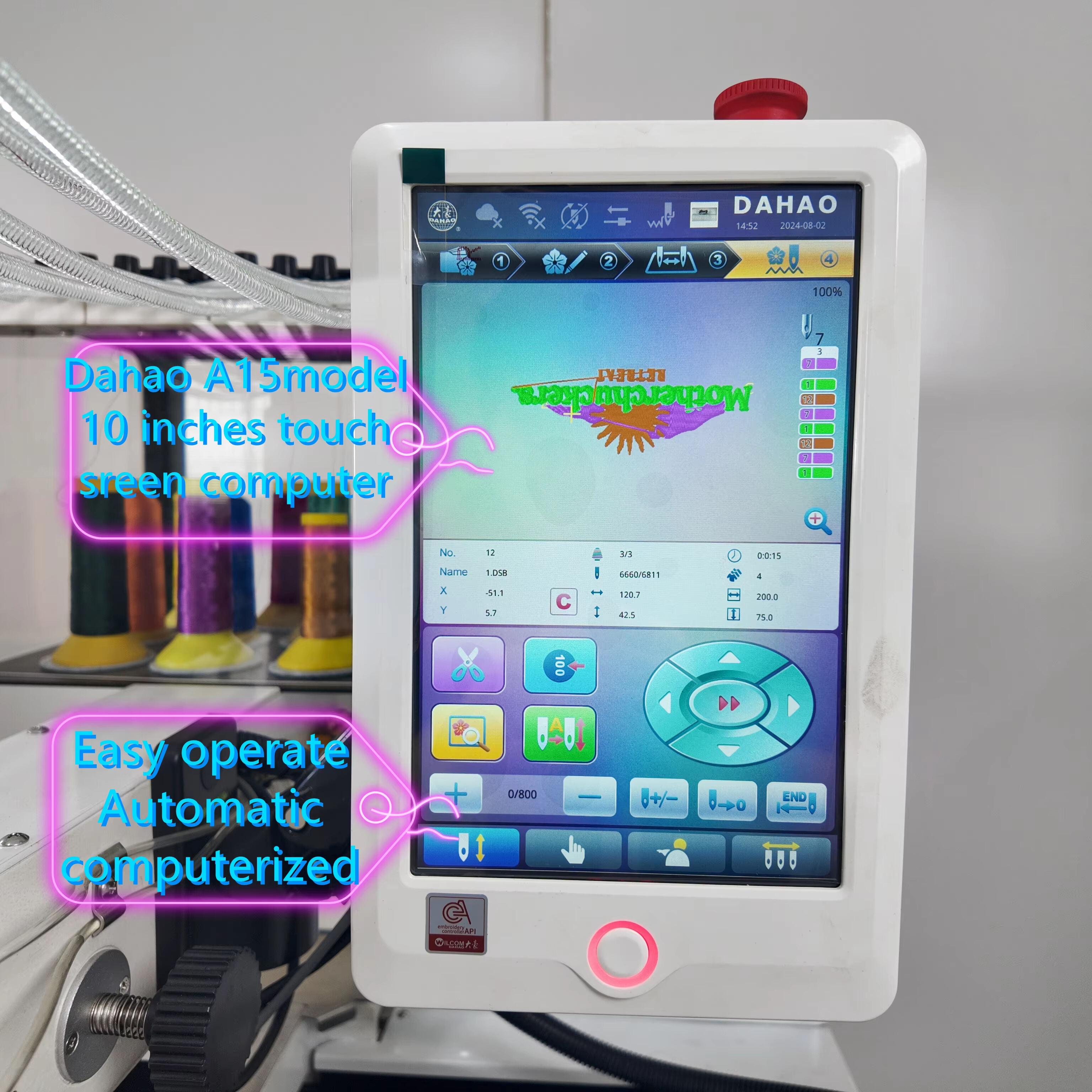

The high quality custom embroidery machine represents a pinnacle of modern textile craftsmanship, combining precision engineering with innovative technology. This advanced system features a robust mechanical framework capable of handling multiple fabric types while maintaining consistent stitch quality. The machine comes equipped with a high-resolution touch screen interface that allows for intuitive design manipulation and real-time monitoring of embroidery progress. With its multi-needle configuration, ranging from 6 to 15 needles, it enables seamless color changes and complex pattern execution. The automatic thread trimming system eliminates the need for manual cutting, while the built-in memory can store thousands of designs for quick access. The machine's advanced tension control system ensures optimal thread tension across different materials, from delicate silks to heavy denims. Its high-speed operation, typically achieving 1,200 stitches per minute, doesn't compromise on precision or quality. The machine also features automatic fault detection, thread break sensors, and an emergency stop function for enhanced safety and reliability. These features make it ideal for both small business operations and industrial-scale production facilities.